Главная → Еmergency equipment → The emergency stop

The emergency stop

The metal sliding stop is intended for fixing a wooden plaster with soft boards and a wooden board on a hole of and also it is intended for strengthening of a partition, waterproof and other closings.

The emergency stop is used for equipment of the vessels and the others floating and stationary constructions at the sea, the rivers, the lakes and the reservoirs.

The emergency stop is our warehouse position you can buy the metal sliding stop without effort.

The emergency stop corresponds to SOLAS 74 , with amendment , to the Rules of Maritime and River Register of Shipping , TC 6418-114-50056342-07 and tested in accordance with the applicable requirements of the IMO Resolutions MSC.81 ( 70 ) and MSC.200 ( 80 ) .

The warranty service life is 1 year .

Version №1: the metal sliding stop 600-400

Version №2: the metal sliding stop 1700-1000

Version №3: the metal sliding stop 2500-1460

|

|

600-400 |

1700-1000 |

2500-1460 |

|

|

600 |

1700 |

2500 |

|

|

3000 |

1500 |

1500 |

|

|

400 |

1000 |

1460 |

|

Mass of the stop, kg |

5,5 |

15,5 |

20 |

The emergency stop is steady against external influences of environment, namely:

- to rotting, corrosion and influence of sea water, oil or fungi;

- to impact of vibration and conditions of storm weather.

Complete set of delivery

In the package of delivery are included the next items:

the emergency stop;

passport.

Purpose:

The metal sliding stop is designed to be mounted on of a hole of the wooden patch with soft sides and of the wooden board, it is also designed to strengthen the bulkhead from water and other closures

The installation of the metal sliding stop contains the following steps:

The installation of the emergency stop is carried out as follows:

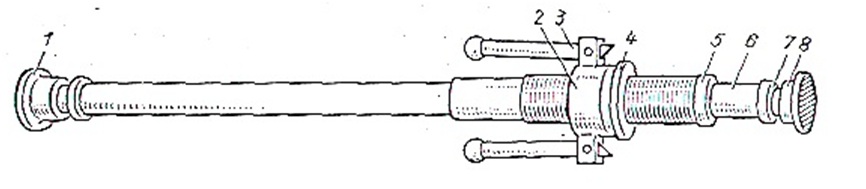

Take the pin 4, the step bearing outer pipe 1 rests on the solid body structure and push the inner tube 6 from the outer tube 5 in such a way that its step bearing 8 approach to establishing a heel patch or shield, and one of the oval cut-outs of the inner tube comes out of the ring nut 2.

Insert the pin 4 into the oval hole of the inner pipe 6.

The rotation of the handle moves the round press nut 2 until it stops at the pin 4, upon the further rotation of which extends the inner tube 6, pressing her step bearing 8 on a wooden plaster or shield.

1 – the step bearing of the outer pipe; 2 - the round press nut; 3 -

lever; 4 – pin; 5 - the outer tube; 6 - the inner tube; 7 – the hinge; 8 - the step bearing of the outer pipe.

Service life

The service life is no more than 10 years.

Safety requirements and environmental protections

The using of the emergency stop don’t require the special security measures.

The using is explosion-proof, fireproof, radiation proof, electrical proof, chemical proof.

3. The operation doesn't exert impact on environment:

there is no chemical, electromagnetic, thermal and biological influences;

toxic, polluting, fire and explosive substances aren't formed.

4. It is necessary to protect the emergency stop from hit of fuels and lubricants and chemically dangerous substances.

5. The utilization is made by the user according to the Federal Law No. 89 F3 "About production wastes and consumption" taking into account regional norms and rules.

Operating instructions

1. Content of entrance control:

1.1. The need of the entrance control and the quantity of the stops which are the subject of the entrance control is defined by the customer (consumer).

1.2 . The visual inspection should be given.

1.3. The content of the external inspection. It is necessary to check the lack of the signs of the critical state, namely the cracks.

1.4 The exploitation of the stop with the signs of the critical state is forbidden.

2. Survey

2.1. The survey of the product is carried out before the installation on the vessel.

2.2. The survey of the product is carried out in the volume of the entrance control.

3. Repairs. The stop isn't the subject to repair.

4. Using of the stop to destination.

4.1. The using of the stop not for the intended purpose is FORBIDDEN.

4.2. The installation of the emergency stop is carried out as follows:

Take the pin, the step bearing outer pipe rests on the solid body structure and push the inner tube from the outer tube in such a way that its step bearing approach to establishing a heel patch or shield, and one of the oval cut-outs of the inner tube comes out of the ring nut.

Insert the pin into the oval hole of the inner pipe.

The rotation of the handle moves the round press nut until it stops at the pin, upon the further rotation of which extends the inner tube, pressing her step bearing on a wooden plaster or shield.

5. Transportation and storage

Transportation conditions: the climate - 4 ( G2 ) in accordance with GOST 15150 for 3 months . Storage conditions: 1.2 according to GOST 15150 (storage with controlled temperature and humidity).